Renewing Our Critical Infrastructure

Force mains are pressurized pipes that use mechanical pumps to keep material moving through them. All pipes degrade over time, eventually needing repair or replacement. Maintaining the St. Louis area’s force mains is a primary focus of MSD Project Clear. Through regular inspections, MSD prioritizes which force mains show the greatest risk of failure. By proactively repairing these sections in a timely manner, we can keep the sewer system functioning at its best without the expense and effort needed to replace pipes or pumps. Following this strategy, MSD not only saves money, we reduce the number of future emergency repairs needed.

In our first three years of visual inspections and testing, MSD has spent approximately $1,000,000 to document the condition of its extensive network of sewers, including approximately 125 miles of force main. The anticipated future benefit is enormous. A single force main emergency can cost between $250,000 and $500,000 to repair. By preventing just two large-scale emergency repairs, MSD will see an immediate return our investment.

Representing MSD’s commitment to effectively managing the maintenance needs of our service area, this program will result in a reduction in force main emergency repairs, a savings for our customers, and a smaller impact on the environment.

By improving the accuracy of our force main mapping, MSD has already seen a drop in the number of emergency repairs. Accidental contractor strikes, in which a contractor breaks a force main, occur more frequently where MSD has incomplete or inaccurate records of the existing force mains. Over the past three years, MSD has undertaken an extensive and sophisticated GPS mapping process to fill the gaps and increase the accuracy of our field records. We have also developed pre-packaged emergency repair kits for each type of force main. These kits are pre-staged ahead of time, reducing response time and expense.

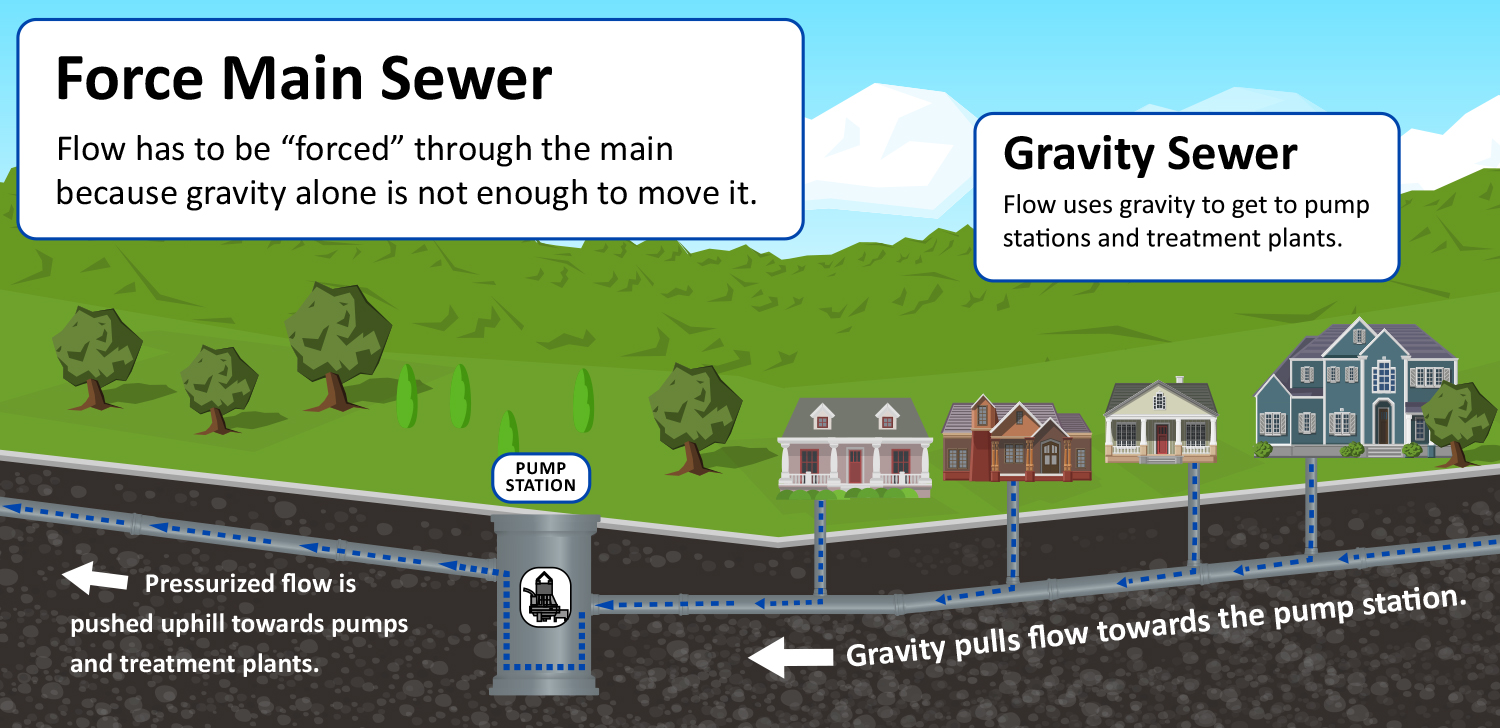

What Are Force Mains, Exactly?

A force main sewer is a sewer line through which wastewater is propelled by the force of pump stations located along its path. Pump stations are sometimes necessary to overcome gravity and allow for the transport of wastewater to area treatment plants. In contrast to “gravity sewers”, which slope downhill to transport material, force mains are used in areas where the pipes are either too low to rely on gravity or they encounter a barrier of some sort. Electric pumps are then needed to move material toward a treatment plant.

Because force mains move material with pumps rather than gravity, they don’t necessarily follow a straight line. Force main alignments can vary by several feet up or down or side to side between access points or pump stations. Determining the exact location needing maintenance or repair can be a challenge. In some cases, force mains were not built exactly to plan and in other cases original plans did not survive the transition to MSD administration years ago.

Today, larger force mains are typically constructed of iron pipes lined with concrete. They can last anywhere from 25 to 50 years, depending on the amount of flow the line handles and the corrosive properties of the wastewater. MSD’s current design practice includes lining the pipe with an epoxy coating to protect it from the corrosive impact of the wastewater flowing through.

Why Pipes Fail

Corrosion is a primary reason a force main needs repair. Depending on pipe material, age, pipe diameter, and other factors, corrosion happens at different rates for different pipes. MSD prioritizes pipe repairs, rehabilitation, and replacements based on a risk-based, asset management strategy balancing the probability of a pipe failure versus the consequence of a failure to the service area (i.e., size of community impact). Those areas with the greatest need where repairs would have the greatest impact are where we focus our efforts.

Visual Inspections

Force mains are classified according to their risk level, which determines how frequently the pipes are inspected by MSD personnel. Based on their categorization, these pipes are placed on a visual inspection cycle. We use three categories of risk to determine how often a visual inspection is conducted. MSD then prioritizes repairs to its force mains based on the results.

- High-risk – once every year

- Medium-risk – once every two years

- Low risk – once every five years

For a real-life example, consider the Caulks Creek force main. It rates as high-risk because of its age (built in 1983), its diameter, and its material (iron pipe).

Using Technology to Identify Risks

In addition to visual inspections, MSD conducts testing to identify potential weak spots within pipes using a variety of sophisticated, specialized, in-pipe technologies. Testing, such as smart-ball testing, occurs only in pipes that are classified as high or medium risk due to the cost and complexity of such assessments.

Smart-ball testing sends an acoustically sensitive, GPS-traceable device through a force main pipe to locate existing leaks or failures. The incoming data highlights potential hot spots in the force main where a higher probability of failure exists. MSD then determines whether continued monitoring or fast-tracked repairs are called for. This enables MSD to repair, rehabilitate, or replace the pipe before a failure occurs or to mitigate the consequences of failure if it does occur.

The inspection techniques employed help MSD identify potential trouble spots in these pipes, enabling staff to conduct small repairs rather than complete replacement. Identifying and responding to trouble spots using technology means a significant cost-savings, benefiting the region as a whole.